56 Chevrolet Pickup

Though our specialty overall is European cars, our collective talents and expertise do not end there.

Our team has the skills and equipment necessary to take on any and all projects that come our way. Large scale, long term projects such as this 1956 Chevrolet Pickup are something we do very well, and for all makes and models.

This classic came to us as a finished project that looked very pretty on the outside, but was, for lack of a better word, a mess underneath.

Underneath the shiny coat of dark purple metallic paint we found fluid leaks, wiring issues, non-functioning sensors, interior concerns, and many other small issues that were in desperate need of attention.

With the “restomod” nature of this truck, (Restomod meaning restored, but modified) there were a lot of parts and modifications that were not factory, and many things had been changed to accommodate these new parts. The engine, suspension, steering, fuel tank, and many electronic components and wiring had been tampered with, meaning lots for us to decipher in order to fix.

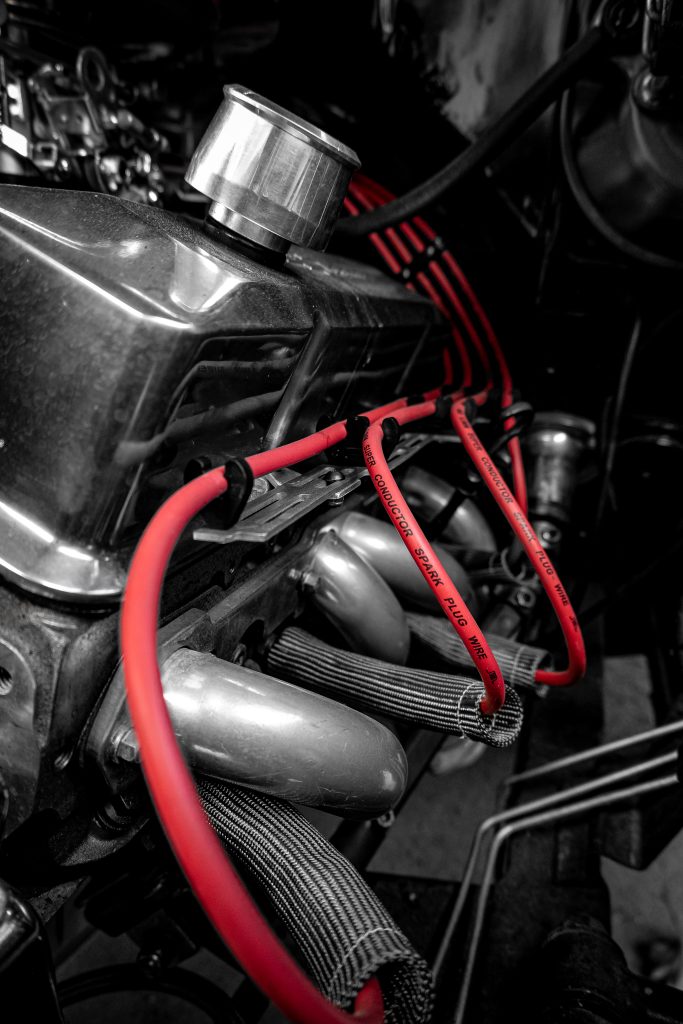

Thankfully, the engine in this truck has no major issues itself. The factory engine was been removed to make way for the tried and tested 5.7L Chevy 350 small block. This is one of the most common engine swaps among domestic vehicles, due to its relatively low cost, simplicity, and wide availability of parts and resources.

Though we don’t have a full build history, we can tell that this truck has an aftermarket intake and carburetor, aluminium cylinder heads, oil pan, and exhaust headers, as well as an upgraded radiator and dressed up chrome accessories.

While it all sounds fast and pretty, when you dig into a project like this that someone else has done, you are venturing into unknown territory. There is not a service manual or single google search out there that will tell you all that you need to know.

Everything needs to be inspected and identified in order to figure out exactly what is going on, and what is causing the issue. Solutions can then be researched and sourced based on our findings, and the necessary repairs can be executed to fix the problem.

Let’s start things off by looking at the electronics.

To say the wiring was a mess would be an understatement. There were exposed contacts, signs of arcing, and overheated terminals throughout the dashboard and interior. This poses a clear fire hazard, and needed to be rectified as soon as possible if the truck was to be enjoyed safely.

We set to work rewiring the truck from bumper to bumper, so that all the interior and exterior functions would once again work as intended. This includes the ignition system, starting/charging system, gauge cluster, radio, HVAC, exterior lights, washer and wiper system, fuel system, and all fuse and power distribution blocks.

We had to strip out all of the bad wiring and start from scratch. New power distribution and fuse blocks were mounted in the engine bay and interior. Once those were in place we could cut to length, insulate, test, and secure the new wiring harness. This is a very complex and tricky process, with dozens of wires to run and keep track of. This was completed for the interior, engine bay, exterior lighting, fuel, and ignition systems.

To fix this we had to hit the books and figure out what signals the gauges wanted to see, and new sending units and oil lines had to be sourced and installed to make the gauges happy. All 3 sending units are now properly communicating with the gauge cluster and display the correct levels.

In the interior we had to rebuild the glovebox that had previously been glued shut, and served only aesthetic purposes.

To make it functional again, the glue had to be stripped away, and a new lock cylinder, hinge, and rubber insulation were fabricated and installed.

On a truck like this that is not going to see use as a daily driver, the glovebox is something that could easily be glued shut and forgotten about, and have little impact on the functionality of the vehicle.

Taking unnecessary shortcuts like that will diminish the value of a classic vehicle, and we could never leave it that way with a clean conscience.

In the dashboard, we installed a period-correct aftermarket Bosch tachometer on the steering column, sourced a high quality replica of the factory instrument cluster to replace the tired and chopped up original unit, and installed a new aftermarket stereo. The heat and AC ducting was in poor condition, so it was rebuilt with all new ducting and connections, and the windshield washer and wiper system had to be redone as well, with a new button installed on the dash to control the fluid.

In the engine bay, we changed the thermostat, faulty starter, and installed a custom MSD ignition wire set with proper heat protection.

The ignition wires on these engines sit very close to the exhaust headers, so to prevent the heat deteriorating the rubber, we installed a set of boot insulators and a set of management brackets at the valve covers to keep the wires organized and out of harm’s way.

We also brought in our friend and carburetor-guru, Larry, who performed some carb tuning to get the engine running perfectly.

The bed had already been dressed up with a very tidy looking wood panel floor and polished steel trim. Over the years the wood planks had fallen into poor condition, and the once-polished finish on the steel trim was looking a bit dull.

We had a woodworking professional come by the shop, who stripped the planks down to good material, and refinished them to keep the bed looking fresh for years to come.

The truck also spent some time in Johnny’s Wax Shop getting a full detail, multi-stage paint correction, and a 5 year Ceramic Coating on the paint and wheels.

A proper paint correction and ceramic coat alone will span several days. Certainly a lengthy process when compared to general detailing, but the end result is well worth it. This durable layer of extra protection will keep the paint looking absolutely flawless for the next 5 years at minimum, as well as making it stay clean longer, and easier to clean when you do need to.

On a project of this scale, there are dozens of small fixes and repairs completed alongside the major repairs, far too many to list here. This simply serves as a general overview of the scope of work that was performed.

Every detail is considered and no shortcut is taken. We pride ourselves on delivering the best end-product possible, every car, every time, and this 1956 Chevy Pickup is the perfect example of that.